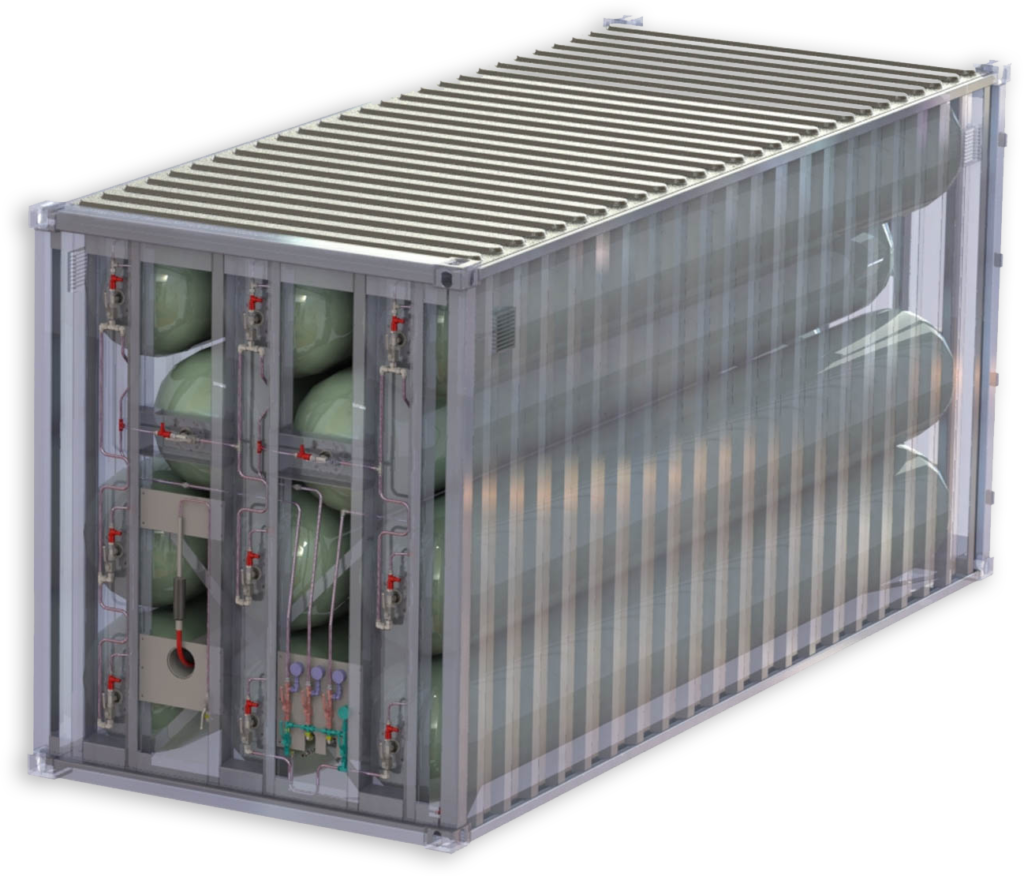

CNG/Biogas and Hydrogen transportation containers

Type 4 ultra lightweight cylinders

Type IV cylinders have plastic lining, stainless steel end fittings and composite construction of high-strength fiberglass and epoxy resin.

The use of such materials eliminates problems with corrosion and also guarantees the absence of galvanic corrosion. The cylinders are tested for a safety factor from 3.2 to 3.4. Cylinder designed for 250 bar, has a burst pressure of 840 bar or higher.

The cylinders are approved for EN 12245 and far exceed the requirements of this standard. This is especially important when testing for defects or impact and fire damage. For operating pressures of 200 and 250 bar, cylinders of various volumes are available. Each cylinder can be up to 2400 liters and is intended for both transport and storage of CNG or BIOGAS. HYDROGEN storage cylinders are also available.

Containers can be filled up to 15 000 times, which gives them a long life.